- 713.590.1312

- sale@pandbtools.com

Understanding Industry Standards for the Best Knife Gate Valves

As industries continue to evolve, the demand for efficient and reliable control systems has never been higher, particularly in the realm of fluid handling.

Knife Gate Valves have emerged as a critical component in various applications, thanks to their ability to provide reliable isolation and throttling capabilities in harsh environments.

According to a recent market analysis by Research and Markets, the global knife gate valve market is expected to grow significantly, reaching over $1.2 billion by 2025, driven by the rising need for energy-efficient solutions across sectors such as water treatment, pulp & paper, and mining.

As technological advancements pave the way for the development of high-performance materials and smarter automation systems, understanding industry standards for the best knife gate valves is essential for ensuring compliance, safety, and operational efficiency in modern industrial applications.

This guide aims to explore the latest trends and best practices for selecting and implementing knife gate valves in various industries.

Knife Gate Valves have emerged as a critical component in various applications, thanks to their ability to provide reliable isolation and throttling capabilities in harsh environments.

According to a recent market analysis by Research and Markets, the global knife gate valve market is expected to grow significantly, reaching over $1.2 billion by 2025, driven by the rising need for energy-efficient solutions across sectors such as water treatment, pulp & paper, and mining.

As technological advancements pave the way for the development of high-performance materials and smarter automation systems, understanding industry standards for the best knife gate valves is essential for ensuring compliance, safety, and operational efficiency in modern industrial applications.

This guide aims to explore the latest trends and best practices for selecting and implementing knife gate valves in various industries.

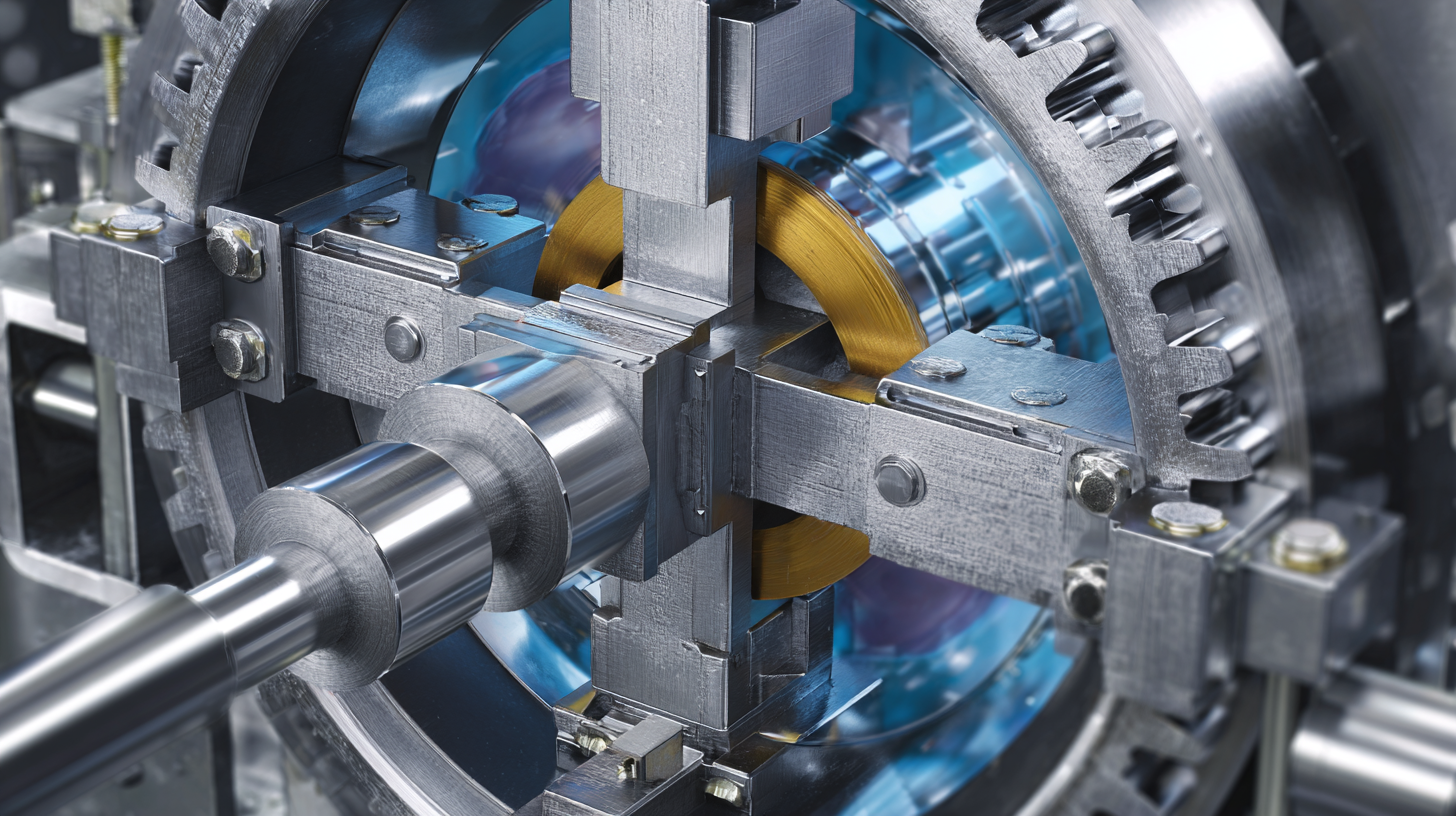

Key Features of High-Quality Knife Gate Valves to Consider

When selecting high-quality knife gate valves, several key features should be taken into consideration to ensure optimal performance and reliability. First and foremost, the valve's construction material plays a critical role. Typically, these valves are available in stainless steel, carbon steel, or ductile iron, each offering distinct advantages for specific applications. According to industry standards, the use of corrosion-resistant materials significantly prolongs the valve's operational lifespan, making it a fundamental aspect of high-quality valve selection.

Another essential feature is the design and sealing arrangement. High-quality knife gate valves often incorporate a full-bore design, allowing for minimal flow resistance and easy cleaning. Furthermore, advanced sealing technologies, such as elastomeric seals, enhance the valve's reliability by preventing leaks under varying pressures. Notably, a report by the Hydraulic Institute highlights that proper sealing can reduce maintenance costs by up to 30%, underscoring the importance of this feature in determining a valve's overall quality.

Lastly, the ease of installation and maintenance should not be overlooked. Valves that are designed for straightforward installation can reduce downtime and labor costs significantly. Recent data from the Valve Manufacturers Association indicate that well-designed knife gate valves with user-friendly features can lead to a 25% reduction in installation time, providing a critical advantage in fast-paced industrial environments.

Key Features of High-Quality Knife Gate Valves

Essential Industry Standards for Knife Gate Valve Performance

Knife gate valves are essential components in various industrial applications, often tasked with controlling the flow of liquids and solids in pipelines. Understanding the essential industry standards for these valves is crucial to ensure optimal performance and safety. According to the American National Standards Institute (ANSI), knife gate valves should comply with the ASME B16.34 standard, which outlines specifications for materials, design, and testing to ensure they can withstand extreme conditions. Compliance with this standard ensures operational efficiency and reduces the risk of valve failure, which could lead to costly downtime.

Moreover, the International Organization for Standardization (ISO) has established ISO 5208, which provides testing procedures for the tightness of valves. Adhering to these standards guarantees that knife gate valves can effectively prevent leakage, an essential factor in protecting both the environment and worker safety. Additionally, a report by the Valve Manufacturers Association (VMA) highlights that valves meeting these stringent standards can enhance system reliability while extending their operational lifespan by 15-30%. Implementing industry standards is not only about compliance but also significantly influences the overall performance and reliability of piping systems in which knife gate valves are used.

Understanding Industry Standards for the Best Knife Gate Valves

| Standard | Description | Applicable Materials | Pressure Rating | Temperature Range |

|---|---|---|---|---|

| ASME B16.34 | Standard for Valves | Steel, Cast Iron | Up to 1500 PSI | -20°F to 750°F |

| API 605 | Full-Bore Gate Valves | Carbon Steel, Alloy Steel | Up to 3000 PSI | -20°F to 250°F |

| DIN 3230 | Technical Specifications for Valves | Stainless Steel, Bronze | Up to 160 bar | -40°C to 200°C |

| ISO 5208 | Industrial Valve Testing | Various Materials | Up to 2500 PSI | -30°C to 120°C |

Top Tips for Selecting the Right Knife Gate Valve for Your Application

When selecting the right knife gate valve for your application, it’s crucial to consider the specific requirements of your industry. Knife gate valves are widely used in sectors such as wastewater treatment, pulp and paper, and mining due to their ability to handle slurries and thick fluids efficiently. According to a report by MarketsandMarkets, the global knife gate valve market is projected to reach $598 million by 2025, driven by advancements in valve technology and increasing demand in industrial processes.

One of the top tips for selecting a knife gate valve is to assess the medium you will be handling. For instance, if you are dealing with viscous or abrasive materials, you should opt for valves made from durable materials like stainless steel or specialized alloys. Additionally, it's vital to determine the pressure and temperature conditions of your application; high-performance models can withstand pressures up to 150 psi and temperatures exceeding 350 degrees Fahrenheit. Proper sizing is also essential; a report from the Valves & Actuators Market indicates that improper valve sizing can lead to inefficiencies and increased operational costs, making it imperative to adhere to manufacturer specifications and industry standards during your selection process.

Common Challenges in Knife Gate Valve Implementation and Solutions

When it comes to knife gate valves, implementing industry standards can often present various challenges. A common issue faced by users is the valve’s ability to effectively seal under different pressure conditions. Inadequate sealing can lead to leaks, resulting in waste and increased operational costs. Understanding the specific requirements of your application is critical to selecting the right valve design and materials, which can mitigate these challenges.

Another challenge is the maintenance and replacement of knife gate valves during their operational life. Users may struggle with accessibility and the time required for upkeep, especially in large-scale industrial setups. One effective solution is having a technical partner who specializes in valve and actuator systems, as they can provide tailored support and supply an updated range of products. By investing in high-quality valves and ensuring proper installation techniques, companies can improve these processes and enhance the longevity of their systems.

Maintenance Best Practices to Extend the Life of Knife Gate Valves

In the realm of industrial applications, knife gate valves are pivotal components, particularly for controlling the flow of slurries and bulk materials. To ensure the longevity and efficiency of these valves, robust maintenance practices are essential. According to industry reports, regular inspection and timely replacements of seals and seats can significantly enhance valve performance, reducing operational downtime by as much as 30%. Furthermore, leveraging innovative technology for predictive maintenance can preempt failures and extend the service life of these critical components.

In the realm of industrial applications, knife gate valves are pivotal components, particularly for controlling the flow of slurries and bulk materials. To ensure the longevity and efficiency of these valves, robust maintenance practices are essential. According to industry reports, regular inspection and timely replacements of seals and seats can significantly enhance valve performance, reducing operational downtime by as much as 30%. Furthermore, leveraging innovative technology for predictive maintenance can preempt failures and extend the service life of these critical components.

During the recent MINExpo 2024, discussions highlighted key strategies for effective maintenance of knife gate valves. For instance, implementing a routine maintenance schedule based on the manufacturer's recommendations can lead to improved reliability and safety. Studies indicate that facilities that adopt such proactive measures experience decreased maintenance costs by up to 25%, while also complying with industry standards. Adopting these best practices not only aligns with industry expectations but also promotes operational excellence in an increasingly competitive marketplace.