- 713.590.1312

- sale@pandbtools.com

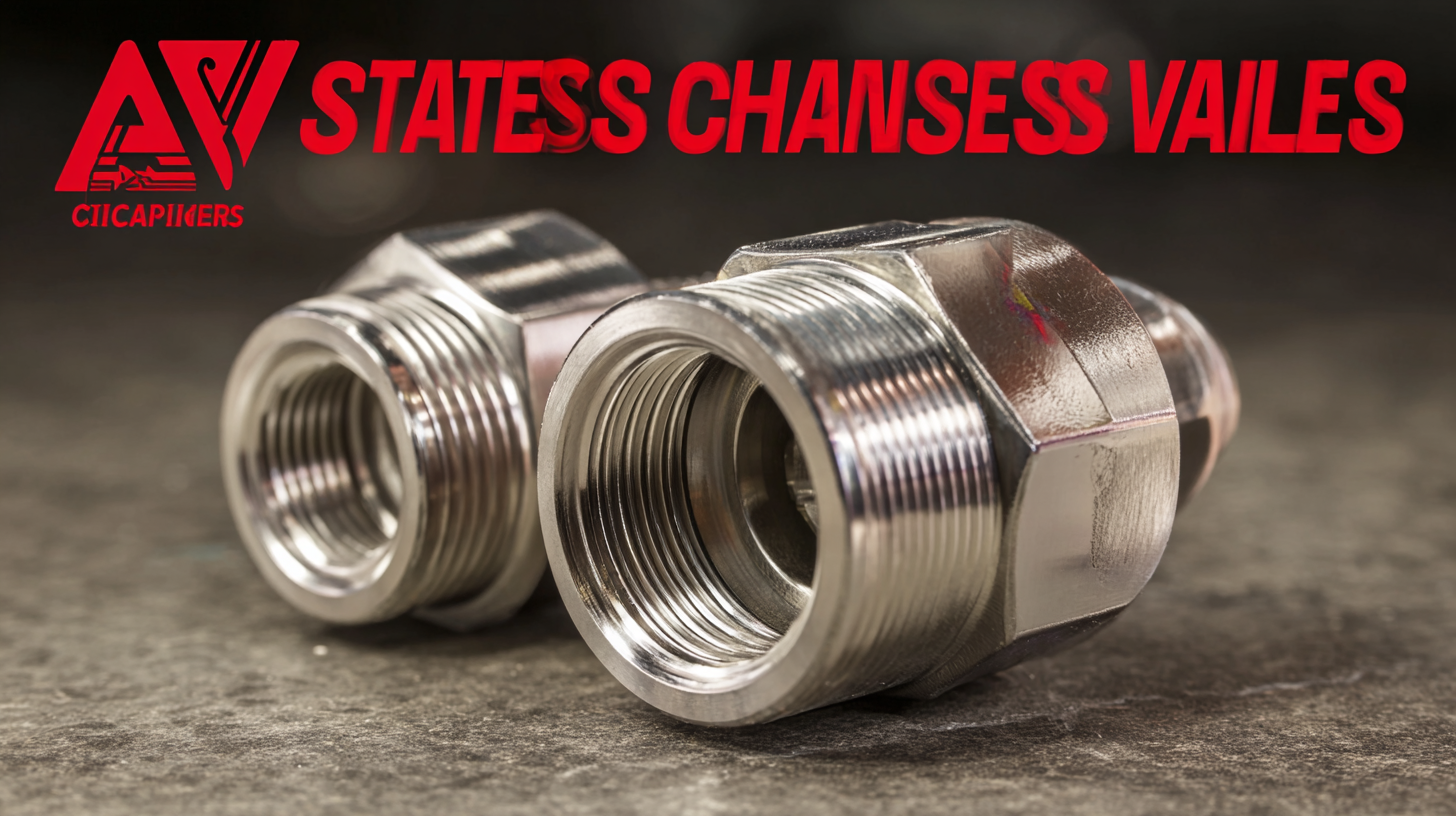

Ultimate Guide to Finding Reliable Suppliers for Best Stainless Check Valves

In the rapidly evolving industrial landscape, the demand for high-quality components such as Stainless Check Valves is escalating significantly. According to a recent market research report by Mordor Intelligence, the global check valve market size is projected to reach USD 8.09 billion by 2026, driven by increasing investments in infrastructure and the rising need for durable and reliable valve systems in various sectors, including oil and gas, water treatment, and chemical processing. As industries continue to strive for efficiency and longevity in their operations, finding reliable suppliers who offer top-notch Stainless Check Valves becomes paramount. This ultimate guide aims to equip you with essential strategies and insights to identify trustworthy manufacturers, ensuring that you make informed decisions that align with your operational needs and quality standards. Emphasizing the motto "Made in China, Shared Globally, Quality You Can Trust," we will explore the critical aspects of supplier selection that can help propel your business forward in a competitive market.

Understanding the Importance of Reliable Suppliers in the Stainless Check Valve Industry

In the stainless check valve industry, the significance of partnering with reliable suppliers cannot be overstated. These suppliers play a pivotal role in ensuring that manufacturers receive high-quality materials, which directly impacts the performance and longevity of the valves. When a manufacturer has access to dependable suppliers, it not only boosts the product's reliability but also enhances the overall reputation of the brand in a competitive market. A reliable supplier is more than just a source for materials; they are a key player in the supply chain that can provide timely deliveries and consistent quality.

Moreover, reliable suppliers offer valuable expertise and support throughout the procurement process. They can guide manufacturers on the latest industry standards and innovations, helping them stay ahead of competitive trends. This partnership can lead to improved product designs and more efficient production processes. Ultimately, by focusing on establishing and maintaining relationships with trustworthy suppliers, companies in the stainless check valve sector can ensure their products meet the highest standards, which is essential for customer satisfaction and long-term success in the industry.

Key Trends in the Stainless Steel Check Valve Market for 2025

As we look towards 2025, the stainless steel check valve market is poised for significant growth, driven by increasing demand across various industries. According to a recent report by Grand View Research, the market is expected to reach approximately $2.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.5% from 2020. This growth is primarily fueled by the rising focus on corrosion resistance and durability that stainless steel offers, making it a preferred material in sectors like oil and gas, water treatment, and chemical processing.

Moreover, key trends indicating a shift towards automation and smart technology in manufacturing processes are expected to redefine the stainless steel check valve market. The integration of IoT and automation technologies in valve systems increases efficiency and reliability while reducing operational costs. Research from MarketsandMarkets predicts that by 2025, around 30% of check valves will incorporate smart features, enabling real-time monitoring and predictive maintenance. This technological advancement is not only enhancing product performance but is also paving the way for suppliers to focus on innovative designs that meet evolving industry standards.

How to Evaluate Supplier Credentials for Stainless Check Valves

When it comes to sourcing stainless check valves, evaluating supplier credentials is paramount to ensure product quality and reliability. According to a recent industry report by Market Research Future, the stainless steel valve market is expected to grow at a CAGR of 5.2% over the next five years, underscoring the importance of partnering with reputable suppliers. Start by assessing the supplier's certifications, such as ISO 9001, which indicates adherence to quality management systems, and CE markings that signify compliance with European safety standards.

Tips for evaluating supplier credentials include requesting product samples and reviewing their quality control processes. A supplier that offers transparency in their manufacturing practices is more likely to produce consistent and high-quality stainless check valves. Additionally, look for suppliers who have been in the market for over a decade and have positive reviews or case studies to back their claims. According to Statista, around 45% of manufacturers highlight supplier reliability as crucial when making procurement decisions. Therefore, prioritize suppliers who demonstrate a solid track record in meeting industry standards and customer satisfaction.

Essential Questions to Ask Potential Suppliers for Check Valves

When searching for reliable suppliers for stainless check valves, asking the right questions is crucial to ensure quality and dependability. Begin by inquiring about their experience in the industry. A supplier with a solid track record and expertise in producing check valves will likely have the necessary knowledge to meet your specific requirements. Ask about the materials they use and whether they adhere to relevant industry standards, as this can impact both performance and safety.

Additionally, consider asking about their quality control processes. Reliable suppliers will have rigorous testing and inspection procedures to guarantee that their products meet specified dimensions and operating standards. Inquire about certifications and compliance with regulations, such as ISO or ASTM, as these can provide insight into their commitment to quality. Finally, don't hesitate to discuss their lead times and flexibility in accommodating custom orders, as these factors can significantly affect your project timelines.

Strategies for Building Long-Term Relationships with Suppliers in 2025

Building long-term relationships with suppliers is crucial for manufacturing companies, especially in the stainless check valve industry. According to a report from the International Valve Manufacturers Association, nearly 75% of companies that prioritize supplier relationships report higher operational efficiency and reduced costs. In 2025, the market will demand suppliers who not only provide quality products but also align with the values of sustainability and innovation.

To foster these long-term relationships, businesses should implement strategies that focus on transparency and communication. Regular meetings to discuss performance metrics, quality issues, and market trends can enhance collaboration. A study from Supply Chain Insights indicates that companies that engage in proactive communication with suppliers witness a 20% increase in supply chain performance. Additionally, fostering mutual support by involving suppliers in product development can lead to innovation, further solidifying the partnership. By prioritizing these strategies, companies can ensure a reliable supply of high-quality stainless check valves while adapting to the evolving market landscape in 2025.