- 713.590.1312

- sale@pandbtools.com

How to Ensure Optimal Performance of Piston Check Valves in Your System

Ensuring optimal performance of Piston Check Valves in various systems is crucial for maintaining efficiency and reliability in fluid dynamics. Piston Check Valves, as critical components in preventing backflow, play a vital role in protecting equipment and ensuring smooth operation across a wide range of applications.

However, without proper maintenance and understanding of their function, these valves can lead to significant operational issues, including reduced efficiency and increased wear and tear.

This guide aims to provide insights into best practices for implementing, maintaining, and troubleshooting Piston Check Valves, ensuring they operate at their peak performance.

By following these recommendations, engineers and technicians can enhance system reliability, minimize downtime, and ultimately extend the lifespan of their fluid control systems.

Ensuring optimal performance of Piston Check Valves in various systems is crucial for maintaining efficiency and reliability in fluid dynamics. Piston Check Valves, as critical components in preventing backflow, play a vital role in protecting equipment and ensuring smooth operation across a wide range of applications.

However, without proper maintenance and understanding of their function, these valves can lead to significant operational issues, including reduced efficiency and increased wear and tear.

This guide aims to provide insights into best practices for implementing, maintaining, and troubleshooting Piston Check Valves, ensuring they operate at their peak performance.

By following these recommendations, engineers and technicians can enhance system reliability, minimize downtime, and ultimately extend the lifespan of their fluid control systems.

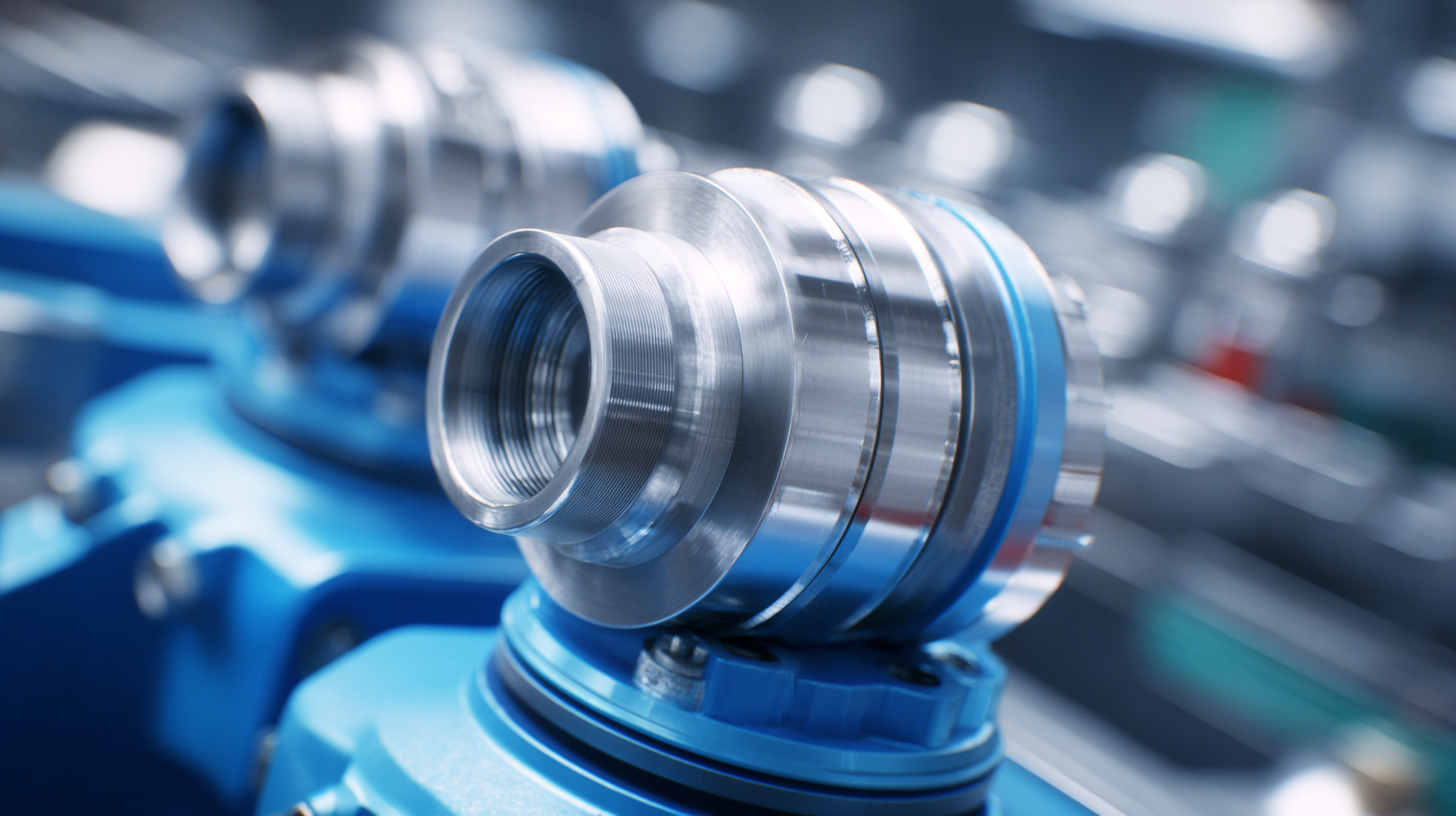

Choosing the Right Material for Piston Check Valves in Your Applications

Choosing the right material for piston check valves is crucial for ensuring their optimal performance in various applications. According to a report by the American Society of Mechanical Engineers (ASME), about 30% of valve failures in industrial systems can be attributed to material incompatibility. This highlights the importance of selecting materials that not only meet operational demands but also resist wear, corrosion, and temperature extremes.

Common materials used in piston check valves include stainless steel, brass, and various polymers. Stainless steel, for instance, is favored for its strength and corrosion resistance, making it suitable for harsh environments, as noted in a study by the Flow Control Society. In contrast, brass provides excellent machinability and is often used in applications with lower pressure and temperature requirements. The selection process should consider factors such as fluid type, system pressure, and environmental conditions to minimize maintenance costs and extend the valve's lifespan—data indicates that proper material selection can enhance the service life of valves by up to 40%.

Design Considerations for Enhanced Performance of Piston Check Valves

When designing piston check valves for optimal performance, several key considerations come into play. The ISA-96 series of standards provides a valuable framework that ensures comprehensive specifications and operational guidelines are met. This helps in maximizing the efficiency of valve actuators which play a crucial role in the functioning of piston check valves. Emphasizing accurate design not only enhances reliability but also significantly improves the overall performance of the fluid control systems where these valves operate.

In addition to adhering to established standards, the materials and geometry of the piston check valves must be meticulously selected. Factors such as flow rates, pressure differentials, and the operational environment can greatly impact performance. It is essential to integrate optimized design principles, including the innovative use of hybrid actuation technologies, which happen to incorporate mechanisms like mechanical diodes. Such advancements can lead to more responsive valve operations and enhanced system efficiency, ultimately resulting in improved engine performance and longevity.

Regular Maintenance Tips to Maximize Lifespan of Piston Check Valves

Regular maintenance of piston check valves is essential to ensure their optimal performance in any fluid system. According to a report by the American Society of Mechanical Engineers (ASME), inadequate maintenance can lead to a 25-30% reduction in valve efficiency over time. Routine inspections should include checking for leaks, ensuring proper seating of the valve, and monitoring for any signs of wear. Implementing a maintenance schedule that includes these checks can significantly extend the lifespan of your valve.

Additionally, keeping a close eye on the operating conditions is crucial. The Hydraulic Institute states that piston check valves can fail prematurely if exposed to conditions outside their specified parameters, such as temperature and pressure fluctuations. Regularly reviewing these parameters and making necessary adjustments can prevent costly downtime and repairs. Furthermore, utilizing appropriate lubricants and cleaning agents can minimize wear and tear, ensuring that the piston check valves function efficiently over the long term. By adhering to these maintenance tips, operators can enhance the reliability and performance of their fluid systems significantly.

How to Ensure Optimal Performance of Piston Check Valves in Your System - Regular Maintenance Tips to Maximize Lifespan of Piston Check Valves

| Maintenance Task | Frequency | Expected Outcome | Recommended Tools |

|---|---|---|---|

| Visual Inspection | Monthly | Identify leaks or damage early | Flashlight, inspection mirrors |

| Cleaning | Quarterly | Prevent clogging and ensure smooth operation | Brush, cleaning solvent |

| Lubrication | Semi-Annually | Reduce wear and tear | Lubricant, grease gun |

| Replacement of Seals | Annually | Maintain proper sealing and function | Seal kit, hand tools |

| Functional Testing | Bi-Annually | Ensure valves are working effectively | Pressure gauges, testing equipment |

Troubleshooting Common Issues with Piston Check Valves

Piston check valves are essential components in many fluid systems, designed to allow flow in one direction while preventing backflow. However, like any mechanical part, these valves can encounter common issues that hinder their performance. One prevalent problem is the presence of debris or sediment that can obstruct the piston movement. Regular maintenance and inspection of the valve can help identify and clear any blockages to ensure smooth operation.

Another common issue is seat wear, which results from prolonged use or exposure to harsh conditions. This wear can lead to leaks and decreased efficiency. To troubleshoot this, operators should frequently check the valve seat for signs of damage and consider replacing components before the problem escalates. Additionally, improper installation and alignment can cause the piston to jam, so it’s crucial to follow the manufacturer’s guidelines during installation and to regularly verify that all components are correctly positioned to minimize operational disruptions. By addressing these issues promptly, the longevity and efficiency of piston check valves can be significantly enhanced.

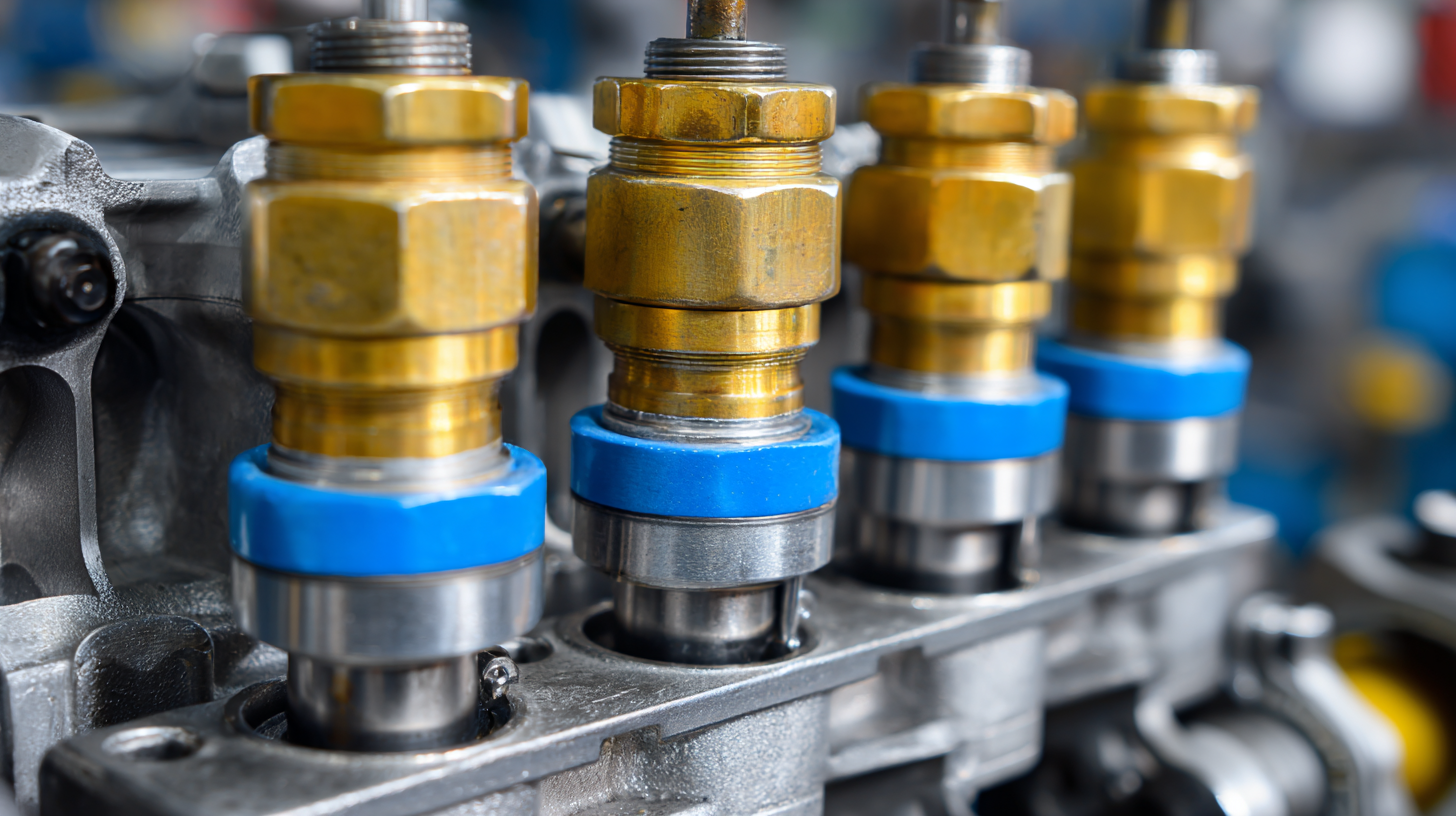

Optimal Installation Practices for Piston Check Valves to Ensure Efficiency

When it comes to maximizing the efficiency of piston check valves in various systems, optimal installation practices are crucial. Proper selection and positioning of check valves ensure that they function correctly, allowing flow in only one direction. This is vital to prevent backflow, which can lead to system failures and inefficiencies in operations. It is important to align the valve with the flow direction indicated on its body, ensuring that it holds up against the required pressures and temperatures.

Additionally, the use of high-quality materials and designs tailored for specific applications can enhance the performance of piston check valves. For instance, double traveling valves have shown significant improvements in efficiency, particularly in rod-pump systems where they can optimize flow management. Selecting the right type, considering factors such as service conditions and compatibility with existing components, can significantly impact the longevity and reliability of the system. Taking the time to install these valves correctly not only boosts efficiency but also reduces the likelihood of costly repairs or replacements in the future.

Related Posts

-

Top 10 Globe Control Valve Manufacturers from China at the 137th Canton Fair

-

10 Best Valve Distributors for Your Industrial Needs

-

7 Essential Benefits of Knife Valves for Efficient Flow Control in Industrial Applications

-

Mastering Flow Valves in Industrial Applications A Comprehensive Tutorial for Beginners

-

Advantages of Using Knife Gate Valves in Various Industries

-

Unlocking Efficiency: The Advantages of Utilizing Cryogenic Ball Valves in Industrial Applications