- 713.590.1312

- sale@pandbtools.com

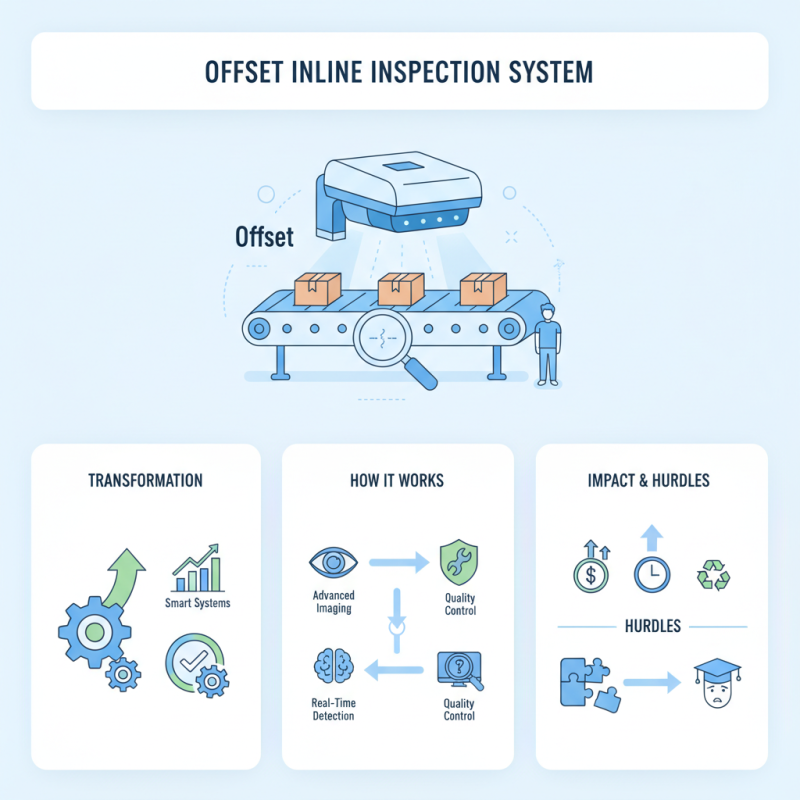

What is an Offset Inline Inspection System and How Does It Work?

The Offset Inline Inspection System (OIIS) has transformed the quality control landscape in various industries. According to a recent report by the International Quality Control Association, 78% of manufacturers have adopted smart inspection systems to enhance product accuracy. These systems streamline processes, reducing labor costs while improving overall efficiency.

Dr. Maria Thompson, a renowned expert in industrial automation, states, "Implementing an Offset Inline Inspection System can significantly mitigate quality risks." In practice, the OIIS monitors products as they move through production lines, detecting issues in real-time. It uses advanced imaging technology that can identify defects not visible to the human eye.

Yet, the implementation of such systems isn't without challenges. Some organizations struggle with integrating OIIS into existing frameworks. Additionally, there are concerns around training personnel to effectively utilize these advanced systems. Despite these hurdles, the potential for increased productivity and reduced waste remains compelling.

What is an Offset Inline Inspection System?

An Offset Inline Inspection System is a specialized tool used in manufacturing. This system scans items as they move along a production line. It identifies defects or inconsistencies in real-time. By doing so, it helps maintain product quality. Many industries benefit from this advanced inspection method.

The process involves high-speed cameras and sensors. These devices capture images and data simultaneously. The system analyzes this information instantly. If a flaw is detected, it can trigger alarms or stop the line. This immediate feedback is crucial for manufacturers. They can address issues before products reach consumers. However, the technology is not flawless. False positives may occur, causing unnecessary stoppages.

Operators must be trained to use these systems effectively. A lack of understanding can lead to mistakes. Regular maintenance is also essential to keep everything running smoothly. Human oversight remains important. People must interpret data and make decisions. Balancing automation and human judgment is a challenge that requires continuous improvement.

What is an Offset Inline Inspection System and How Does It Work?

| Feature | Description | Importance |

|---|---|---|

| Real-time Inspection | Allows for immediate detection of defects as products are being manufactured. | Enhances quality control and reduces waste. |

| Offset Technology | Utilizes offset angles for better alignment and accuracy in measurements. | Increases inspection precision and consistency. |

| Data Analytics | Collects and analyzes data trends over time to improve manufacturing processes. | Provides insights that help in proactive decision-making. |

| Integration with Production Line | Seamlessly integrates into existing production lines without major overhauls. | Minimizes downtime and operational disruptions. |

| User-Friendly Interface | Features an intuitive interface for easy monitoring and adjustments. | Facilitates quick training and adaptation for operators. |

Key Components of an Offset Inline Inspection System

Offset inline inspection systems play a crucial role in various industries. These systems are designed to identify defects during the production process. They do this without halting the workflow, ensuring efficiency.

Key components of an offset inline inspection system include cameras and sensors. Cameras capture images of the products as they move along the production line. Sensors measure dimensions and detect any discrepancies. Each component works together to ensure accuracy. The system also includes software that analyzes the data collected. It can alert operators when issues arise, preventing defective products from reaching customers.

However, not all systems are foolproof. Some might miss subtle defects. Operators may need additional training. The system requires regular maintenance to function optimally. A small oversight can lead to significant problems down the line. Continuous improvement and reflection are essential for enhancing performance and reliability.

How Does an Offset Inline Inspection System Operate?

An Offset Inline Inspection System represents a significant advancement in quality control processes. It utilizes a combination of sensors and cameras to assess products during production. This method reduces the need for separate inspection stations. Thus, it saves time and streamlines workflow.

During operation, products move through a conveyor system. Specialized cameras capture images, while sensors detect physical properties. This real-time data is analyzed instantly. If a defect is spotted, the system can alert operators. Yet, there may be instances where errors occur. False positives can lead to unnecessary alarms. Operators need to discern real issues from trivial flaws.

The system's efficiency also hinges on calibration. Regular adjustments are necessary to maintain accuracy. When overlooked, it can result in missed defects. Human oversight is still essential. Automation has limitations, and careful monitoring is crucial. It’s a balance between technology and human judgment.

Benefits of Using an Offset Inline Inspection System

Offset Inline Inspection Systems offer several advantages that enhance manufacturing processes. One significant benefit is improved product quality. By inspecting products in real-time, defects can be detected immediately. This reduces the need for rework and minimizes waste. Real-time feedback helps operators to make quick adjustments, which can enhance both efficiency and effectiveness.

Another important aspect is cost savings. With an offset inspection system, manufacturers can identify issues before they escalate. This proactive approach helps in reducing scrap rates and labor costs associated with faulty products. Streamlined processes lead to better resource allocation. However, integrating these systems can be challenging. Training staff and adjusting workflows may require effort and time.

Offset systems also empower manufacturers to maintain compliance with industry standards. They provide documentation and data for audits. This can improve overall credibility in the marketplace. Yet, some companies may struggle with the initial investment and perceived complexity. Balancing the upfront costs with long-term savings is crucial. These systems offer notable benefits, but reflection on the implementation process is essential.

Benefits of Using an Offset Inline Inspection System

Common Applications of Offset Inline Inspection Systems

Offset inline inspection systems are essential in various industries. They help ensure product quality and operational efficiency. Common applications include the automotive, food, and pharmaceutical sectors. In the automotive industry, these systems allow for real-time monitoring of parts during production. According to recent industry reports, over 75% of manufacturers use inline systems to detect defects early. This reduces waste and saves costs.

In food production, offset inspection systems ensure compliance with safety standards. They can check packaging integrity and product consistency. Studies show that implementing such technology can reduce contamination risks by 50%. This is pivotal in maintaining consumer trust, especially in the wake of food safety scandals.

Pharmaceutical companies benefit significantly, too. They rely on these systems for batch verification and expiration tracking. A report indicated that 60% of pharmaceutical firms have adopted inline inspection to enhance accuracy. Yet, challenges remain. Not all products fit seamlessly into existing inspection frameworks. This highlights the need for continuous improvement in system adaptability and precision.