- 713.590.1312

- sale@pandbtools.com

Mastering Flow Valves in Industrial Applications A Comprehensive Tutorial for Beginners

In the realm of industrial applications, mastering Flow Valves is paramount for optimizing efficiency and ensuring system reliability. As reported by the International Society of Automation, approximately 30% of industrial energy loss can be attributed to inefficient valve operations.

Flow Valves play a crucial role in controlling the flow of fluids within various processes, impacting everything from manufacturing productivity to the sustainability of energy consumption.

According to a recent report by MarketsandMarkets, the global market for industrial valves is projected to reach $80.6 billion by 2024, emphasizing the significance of understanding different types and their applications.

This tutorial aims to provide beginners with a comprehensive overview of Flow Valves, highlighting their types, functions, and critical applications, ensuring that readers can make informed decisions that contribute to both operational excellence and environmental stewardship.

Flow Valves play a crucial role in controlling the flow of fluids within various processes, impacting everything from manufacturing productivity to the sustainability of energy consumption.

According to a recent report by MarketsandMarkets, the global market for industrial valves is projected to reach $80.6 billion by 2024, emphasizing the significance of understanding different types and their applications.

This tutorial aims to provide beginners with a comprehensive overview of Flow Valves, highlighting their types, functions, and critical applications, ensuring that readers can make informed decisions that contribute to both operational excellence and environmental stewardship.

Understanding the Basics of Flow Valves: Types and Functions

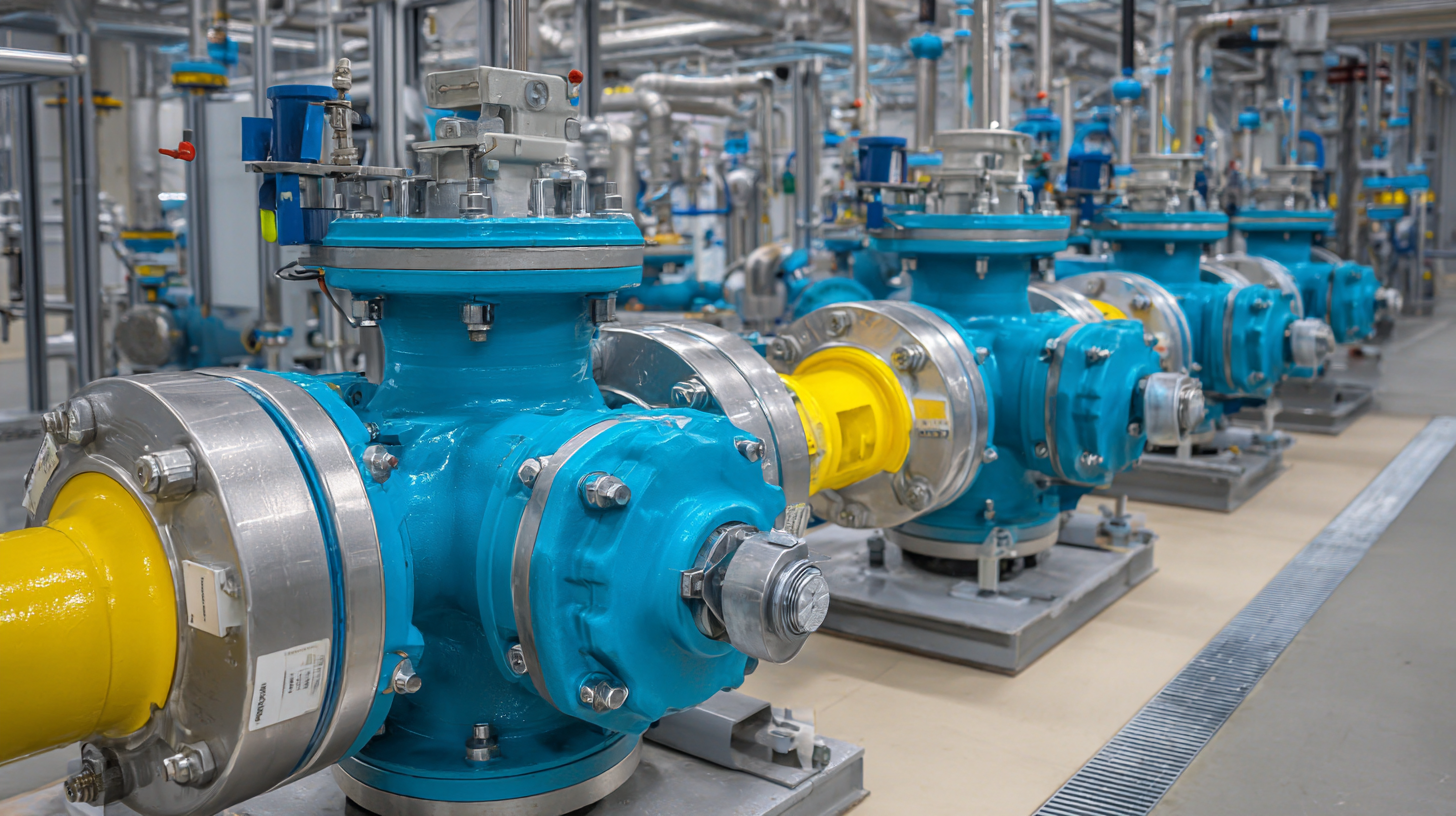

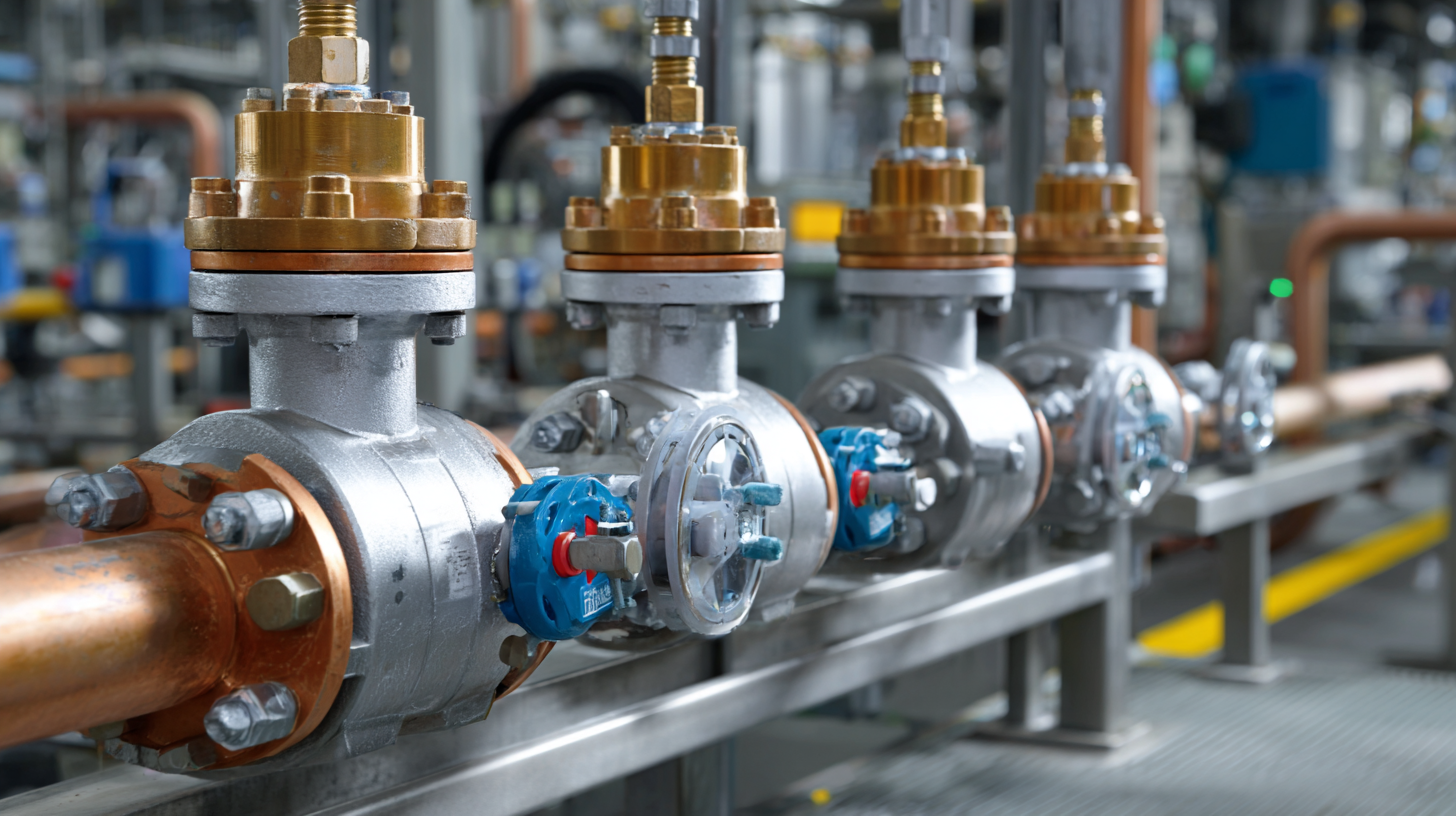

Flow valves are essential components in various industrial applications, serving critical roles in controlling the movement and direction of fluids. Understanding the basics of flow valves is vital for beginners aiming to grasp their functionality. There are several types of flow valves, including globe valves, ball valves, butterfly valves, and check valves, each designed to fulfill specific operational requirements.

Globe valves, known for their good throttling ability, are commonly used to control flow rates, while ball valves provide quick shut-off capabilities, making them a popular choice for on-off applications.

Globe valves, known for their good throttling ability, are commonly used to control flow rates, while ball valves provide quick shut-off capabilities, making them a popular choice for on-off applications.

The functions of flow valves extend beyond mere flow regulation; they are also instrumental in preventing backflow and ensuring system stability. Cavitation, a phenomenon that occurs when pressure within a valve drops significantly, can lead to damaging vibrations and noise if not properly managed. By understanding the various types and functions of flow valves, industrial operators can optimize system performance, enhance efficiency, and reduce maintenance costs in their applications. Moreover, knowledge of valve dynamics paves the way for informed decision-making in industrial design and process management.

Key Components of Flow Valves and Their Role in Industrial Systems

Flow valves are essential components in industrial systems, playing a significant role in controlling the direction and rate of fluid movement. They come in various types, including ball, gate, and globe valves, each designed for specific applications. Understanding their key components, such as the actuator, seat, and stem, is crucial for beginners looking to master their use. The actuator provides the necessary force to open or close the valve, while the seat creates a tight seal to prevent leaks. The stem connects the actuator to the valve disc, facilitating smooth operation.

Tip: When selecting flow valves, always consider the fluid characteristics and system requirements. This ensures optimal performance and longevity, reducing maintenance costs in the long run. Additionally, pay attention to the valve's pressure rating, as exceeding this limit can lead to catastrophic failures.

In industrial systems, flow valves also play a vital role in safety and automation. They can be integrated into control systems, allowing for real-time adjustments based on process demands. For instance, in a chemical processing plant, flow valves can help regulate the flow of reactants to maintain optimal reaction conditions.

Tip: Regularly inspect and maintain flow valves to ensure they are functioning correctly. Implementing a schedule for routine checks can help identify issues early, preventing costly downtime.

Installation Guidelines: Ensuring Optimal Performance of Flow Valves

When it comes to the installation of flow valves in industrial applications, following precise guidelines is crucial for ensuring optimal performance. Before beginning the installation process, it's essential to assess the location and determine the correct size and type of valve required for your system. Ensure all surfaces where the valve will be installed are clean and free from contaminants. This sets the stage for a proper seal and performance.

Tip: Always refer to the manufacturer’s specifications during installation. Each valve model may have unique requirements regarding orientation and mounting dimensions. Installing a valve incorrectly can lead to inefficient flow control or even damage to adjoining components in your system.

After positioning the valve, pay close attention to the tightening procedure. Over-tightening can lead to stress fractures, while under-tightening may result in leaks. Use a torque wrench to ensure that all fittings are tightened to the specified torque levels.

Tip: It’s wise to use a thread sealant for threaded connections to enhance leak prevention. Regularly inspect installed valves to ensure they are functioning correctly and maintain a log of any maintenance performed, which aids in future troubleshooting and repairs.

Flow Valve Performance in Industrial Applications

Common Issues with Flow Valves: Troubleshooting Tips for Beginners

Flow valves play a crucial role in industrial applications, controlling the movement of liquids and gases within a system. However, like any mechanical components, flow valves can encounter issues that affect their performance. One common problem is valve leakage, which contributes to inefficiencies and can lead to significant operational costs. According to a report by the American Society of Mechanical Engineers (ASME), leaks in industrial systems can result in a loss of up to 30% of the fluid being managed, demonstrating the importance of troubleshooting and maintenance in optimizing valve functionality.

Another prevalent issue is valve sticking, often resulting from debris or corrosion within the valve assembly. This can lead to unpredictable flow rates and erratic system behavior. A study conducted by the International Institute of Refrigeration revealed that regular maintenance could reduce sticking problems by nearly 50%, underscoring the significance of proactive troubleshooting tactics. Ensuring that flow valves are properly maintained and regularly inspected can help mitigate these issues, improving the reliability and efficiency of industrial processes. By understanding and addressing these common challenges, beginners can enhance their familiarity with flow valves and contribute to smoother operational workflows.

Mastering Flow Valves in Industrial Applications

| Issue | Description | Possible Causes | Troubleshooting Tips |

|---|---|---|---|

| Leakage | Fluid escaping from the valve | Worn seals, damaged valve body, or incorrect installation | Inspect seals and body for damage; replace as necessary |

| Sticking Valve | Valve does not open or close properly | Dirt or debris buildup, corrosion | Clean the valve thoroughly; apply lubricant if applicable |

| Unstable Flow | Irregular fluid flow through the valve | Incorrect sizing, pressure changes | Check sizing specifications; adjust pressure as needed |

| Noise | Unusual sounds during operation | Vibration or cavitation | Inspect installation for tightness; check for cavitation and resolve |

| Pressure Drop | Decrease in pressure across the valve | Clogged filters or strainers, valve malfunction | Inspect and clean filters; check valve operation |

Best Practices for Maintaining Flow Valves in Industrial Settings

Maintaining flow valves in industrial settings is crucial for ensuring efficient operation and preventing costly downtime. Regular inspection and maintenance can significantly extend the lifespan of these valves. One of the best practices is to establish a routine maintenance schedule. This should include regular checks for leaks, wear, and proper functioning to identify potential issues before they escalate.

Tips for maintaining flow valves include ensuring that the valve is correctly installed and aligned, as misalignment can lead to premature wear. It’s also essential to keep the valve clean and lubricated according to manufacturer specifications. This not only helps in maintaining smooth operation but also prevents contamination that could affect overall system performance. Furthermore, testing the valve's function regularly can help in ensuring it responds appropriately under varying pressures and flow conditions.

Another important consideration is to use the right materials for repairs and replacements, as mismatched components can lead to failures. Keeping accurate records of maintenance activities can also aid in identifying patterns or recurring issues, allowing for more targeted interventions. Consistent attention to these practices will ensure optimal performance and safety in the industrial environment.