- 713.590.1312

- sale@pandbtools.com

Exploring the Innovations Shaping the Future of Angle Valves

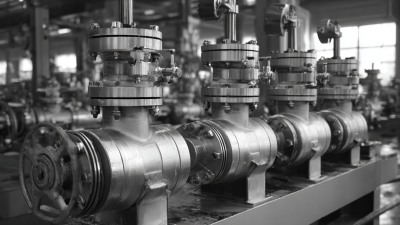

In an era marked by rapid technological advancements and evolving industrial needs, Angle Valves are emerging as a pivotal component in fluid control systems. Their unique design, which allows for optimal flow direction and space efficiency, positions these valves at the forefront of innovation in various applications, from plumbing to chemical processing.

As industries face increasing demands for precision, durability, and efficiency, understanding the innovations shaping the future of Angle Valves becomes essential. This blog will delve into the latest developments in Angle Valves, exploring their types, functionalities, and the groundbreaking technologies driving their evolution. By shedding light on these advancements, we aim to provide insights into how Angle Valves are not just responding to current needs but are also anticipating future challenges, ensuring reliability and performance in an ever-changing landscape.

As industries face increasing demands for precision, durability, and efficiency, understanding the innovations shaping the future of Angle Valves becomes essential. This blog will delve into the latest developments in Angle Valves, exploring their types, functionalities, and the groundbreaking technologies driving their evolution. By shedding light on these advancements, we aim to provide insights into how Angle Valves are not just responding to current needs but are also anticipating future challenges, ensuring reliability and performance in an ever-changing landscape.

Trends in Angle Valve Design: Balancing Efficiency and Sustainability

The angle valve industry is undergoing transformative changes driven by trends that prioritize both efficiency and sustainability. According to the latest report by ResearchAndMarkets, the global market for industrial valves, including angle valves, is expected to reach $100 billion by 2025, with a compound annual growth rate (CAGR) of 5.4%. This growth is largely attributed to the increasing demand for energy-efficient solutions across various sectors, including water management and process industries. Angle valves, with their unique design that allows for better fluid control and reduced pressure loss, are becoming essential components in achieving these operational efficiencies.

Sustainability is a critical consideration in the redesign of angle valves, with manufacturers investing in

eco-friendly materials and innovative technologies. A recent study by MarketsandMarkets highlights that over 60% of valve manufacturers are now focusing on

developing products that not only comply with environmental regulations but also help in reducing carbon footprints.

Biodegradable materials and the integration of IoT technology are at the forefront of this shift, enabling

real-time monitoring and maintenance of systems to minimize waste and enhance lifespan. As the industry continues to evolve, these trends promise to make angle valves not only

more efficient but also pivotal in sustainable engineering practices.

Smart Technologies Revolutionizing Angle Valve Functionality

In recent years, the integration of smart technologies has begun to revolutionize the functionality of angle valves, elevating them far beyond traditional mechanical devices. These innovations, driven by advancements in IoT (Internet of Things), have enabled angle valves to offer remote monitoring and control capabilities. For instance, smart sensors can now provide real-time data regarding flow rates, pressure levels, and valve positions, allowing operators to make informed decisions on-the-fly. This shift not only enhances operational efficiency but also significantly reduces the risk of unexpected failures, fostering a more reliable infrastructure.

Moreover, the application of AI algorithms in the management of angle valves is proving to be a game-changer. Smart angle valves equipped with predictive maintenance features can analyze usage patterns and anticipate potential issues, thereby preventing costly downtimes. This proactive approach ensures that maintenance is conducted precisely when needed rather than relying on reactive measures. As smart technologies continue to advance, angle valves are evolving into intelligent components that contribute to more sustainable and efficient industrial processes, paving the way for a new era in fluid control systems.

Material Innovations: Enhancing Durability and Performance in Angle Valves

Angle valves are crucial components in various industrial applications, and their performance largely depends on the materials used in their construction. Recent advances in material science have introduced innovative options such as

duplex stainless steel and

polymer-based composites, enhancing durability and corrosion resistance. According to a report by MarketsandMarkets, the global valve market is expected to grow from

USD 74.9 billion in 2020 to

USD 106.4 billion by 2026, underscoring the increasing demand for high-performance angle valves in diverse sectors.

One key innovation is the use of ceramic coatings, which significantly improve wear resistance and extend the lifecycle of angle valves. These coatings can reduce friction and prevent material degradation, resulting in lower maintenance costs and increased uptime for industrial operations. Additionally, advancements in additive manufacturing allow for customized valve designs that can optimize fluid dynamics, further improving efficiency and performance.

Tips: When selecting angle valves, consider the specific environmental conditions they will face, such as temperature extremes or exposure to corrosive chemicals. Choosing the right material can make a significant difference in both performance and longevity. Additionally, investing in

high-quality, well-engineered angle valves can lead to substantial cost savings in terms of repairs and replacements in the long run.

Regulatory Challenges and Compliance in Angle Valve Manufacturing

The manufacturing of angle valves is evolving rapidly, driven by innovations in technology and increasing demand for performance and efficiency. However, navigating the regulatory landscape presents a significant challenge for manufacturers. Compliance with safety standards and environmental regulations is paramount, and any lapse can lead to severe penalties or product recalls. Staying abreast of the latest regulations and understanding the implications for design and production is essential for success in this competitive sector.

Tip: Regularly engage with regulatory bodies and industry associations to ensure you are updated on the latest compliance requirements. This proactive approach can help mitigate risks and facilitate smoother production processes.

Moreover, manufacturers must also focus on sustainable practices. Many regulators are pushing for eco-friendly materials and processes, which means that angle valve makers need to rethink their supply chains and manufacturing techniques. Implementing sustainable practices not only helps in regulatory compliance but can also enhance brand reputation in a market increasingly focused on environmental responsibility.

Tip: Consider adopting green certifications for your products and operations. This not only aids compliance but also appeals to eco-conscious customers, positioning your brand as a leader in sustainability.

Future Perspectives: The Role of Angle Valves in Smart Infrastructure Solutions

As the world increasingly turns towards smart infrastructure solutions, angle valves are set to play a pivotal role in this transformation. These valves are not just critical components in fluid control; their ability to integrate with advanced technologies positions them as essential elements in modern industrial systems. The global industrial valve market is poised for significant growth, projected to rise from USD 84.97 billion in 2025 to USD 128.22 billion by 2035, indicating a compound annual growth rate (CAGR) of 4.2%. This growth reflects the increasing importance of innovative valve designs, including angle valves, which facilitate efficiency and control in smart applications.

Tips for leveraging angle valves in smart infrastructure include evaluating their compatibility with IoT-enabled systems for real-time monitoring and control. Additionally, consider the materials and designs that enhance durability and reduce maintenance needs, ensuring long-term performance in dynamic environments.

Furthermore, adopting automation in angle valve operation can enhance system responsiveness and integrity, further supporting the seamless integration of smart technologies into existing infrastructures. As we move towards an increasingly automated future, angle valves will be at the forefront of developing systems that are not only efficient but also adaptive to future needs.

Innovations in Angle Valves for Smart Infrastructure

This chart illustrates the adoption of various innovations in angle valves that are shaping the future of smart infrastructure solutions.

Related Posts

-

Understanding Industry Standards for the Best Knife Gate Valves

-

Innovative Approaches to Using Best Steam Valves in Industrial Applications

-

10 Best Valve Distributors for Your Industrial Needs

-

Unlocking Efficiency in Manufacturing with the Best Swing Valve Applications and Installation Guide

-

What is a Flanged Gate Valve and Why It’s the Best Choice for Your Industrial Needs?

-

Unlocking Efficiency: The Advantages of Utilizing Cryogenic Ball Valves in Industrial Applications