- 713.590.1312

- sale@pandbtools.com

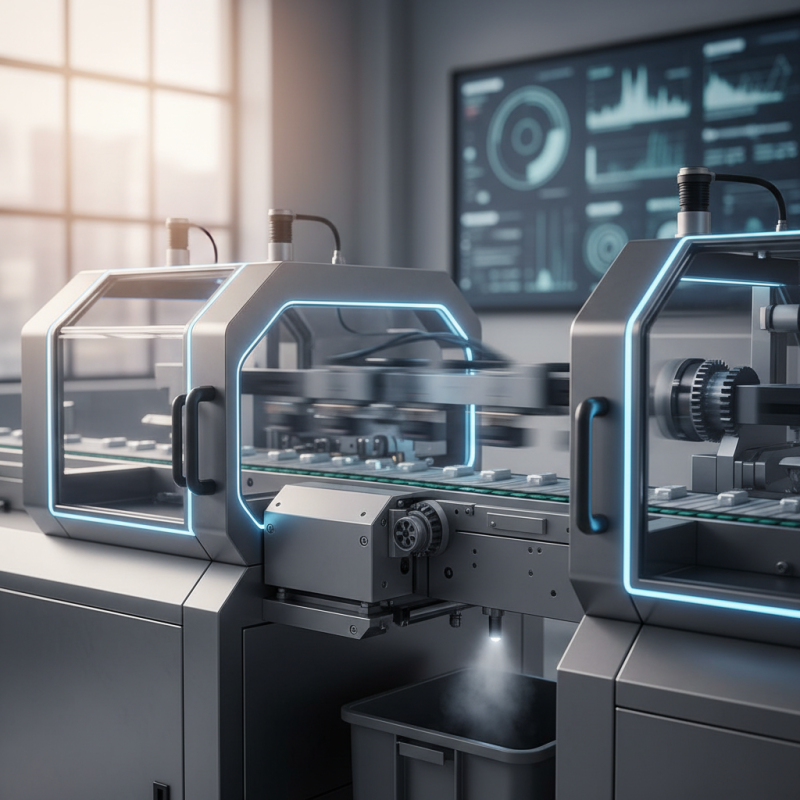

Why Choose a High Speed Inspection Machine for Your Business?

In today's competitive market, efficiency is crucial. Many businesses are turning to advanced technology. A High Speed Inspection Machine is at the forefront of this change. It enhances productivity and ensures quality control simultaneously.

Imagine producing thousands of items in a day. Each requires careful scrutiny. Traditional methods may lead to human error. A High Speed Inspection Machine can identify defects quickly. This swift analysis safeguards your brand’s reputation. It enables a steady flow of goods, reducing downtime.

However, adopting such technology comes with challenges. Initial costs can be significant. Staff may require training. Businesses must weigh these factors carefully. Despite its advantages, a High Speed Inspection Machine is not a panacea. It demands investment and careful integration into workflows.

Benefits of High Speed Inspection Machines in Manufacturing

In modern manufacturing, high-speed inspection machines are becoming essential. These machines can significantly enhance efficiency. According to industry reports, companies that invest in high-speed inspection can reduce defect rates by up to 30%. This means fewer customer complaints and lower costs for recalls.

Speed is not the only benefit. High-speed inspection can streamline workflows. The automation of quality checks enables real-time data collection. This provides valuable insights into production quality. A study found that businesses integrating high-speed systems reported a 20% increase in overall productivity. Streamlined processes lead to timely deliveries and improved customer satisfaction.

Tip: Regular maintenance of inspection machines is crucial. Neglect can lead to unexpected downtimes. Consider setting a maintenance schedule to prolong the life of the equipment.

Equally important, the data collected can reveal patterns. This can guide companies in avoiding potential quality issues. However, not all machines are created equal. It’s vital to evaluate the specific needs of your operation. Blindly investing in the fastest option may not yield the best results. Tailoring the technology to fit your processes is key to maximizing benefits.

Enhancing Product Quality and Reducing Defects with Speed

In today's fast-paced market, quality is non-negotiable. A high-speed inspection machine can significantly enhance product quality. These machines quickly identify defects that might escape the human eye. For example, in a food processing line, inconsistencies in packaging can lead to spoilage. An inspection machine catches these errors, preventing costly recalls.

Speed is vital. Quick inspections mean products reach consumers faster. However, high speed shouldn't compromise accuracy. Operators need to regularly calibrate machines to maintain reliability. In some cases, inspection speed may reveal new issues. A machine might flag a subtle defect, prompting a deeper investigation. This process creates a feedback loop, driving continuous improvement.

Investing in high-speed inspection is a strategic decision. It doesn’t just save time; it cultivates a culture of quality within the organization. However, it’s crucial to ensure that all team members are trained to respond to the machine's findings. Without proper training, the benefits of inspection speed could be lost. Balancing speed and thoroughness is a challenge that requires constant reflection.

Streamlining Operations and Increasing Efficiency through Automation

High-speed inspection machines are transforming industries. They enhance operations and boost efficiency. Automation is the key to this transformation. Research shows that automating inspection processes can improve accuracy by up to 30%. This can lead to reduced human error. Errors can cost businesses time and money. By using high-speed machines, companies can minimize these risks.

In addition, speed plays a crucial role. High-speed machines can inspect products at rates exceeding 1,000 units per minute. This is important in fast-paced industries. A report from the Automation Industry Association states that businesses can increase throughput by 25% with automation. This efficiency allows for quicker product delivery. Customers value speed. They often choose suppliers who can meet their needs faster.

Despite these benefits, challenges exist. Some companies face initial costs that are daunting. Training staff to operate new machinery can also be a hurdle. Not all employees adapt quickly. There may be resistance to the change. However, overcoming these challenges is vital for long-term success. Businesses must weigh the immediate discomfort against future gains. In the end, high-speed inspection machines could prove to be invaluable assets.

Cost Savings and Return on Investment from High Speed Inspection

Investing in a high-speed inspection machine can significantly enhance operational efficiency and save costs. Reports indicate that companies implementing such technology see a reduction in inspection time by up to 40%. This means fewer labor hours needed for quality checks, leading to lower operational expenses. Many manufacturers overlook this potential, yet even small adjustments in speed can result in substantial financial benefits.

In the long run, the return on investment (ROI) from these machines is notable. Research from industry analysts shows that businesses can achieve an ROI of over 300% in three years. This increase stems from improved product quality and decreased waste rates. Companies that remain hesitant may find themselves lagging behind competitors who leverage these advanced inspection technologies.

However, it’s essential to consider the initial investment and maintenance costs. Some organizations face challenges in training staff to adapt to new systems. This transitional period can temporarily disrupt operations. Yet, those who navigate these hurdles typically gain a competitive edge. Investing in high-speed machines might seem daunting, but the cost savings and ROI often outweigh initial fears. Understanding how to balance these factors will determine long-term success.

Cost Savings and ROI of High Speed Inspection Machines

This chart illustrates the financial aspects of adopting a high-speed inspection machine. The initial investment, ongoing maintenance, labor costs, and quality control costs are compared against the expected return on investment over time, highlighting potential cost savings and the efficiency it can bring to your business operations.

Choosing the Right High Speed Inspection Machine for Your Needs

When selecting a high-speed inspection machine, it's essential to assess specific needs. Consider factors such as speed, accuracy, and the types of products you'll be inspecting. A recent industry report noted that 70% of manufacturers saw significant efficiency improvements when implementing high-speed inspection systems. These machines can operate at speeds exceeding 300 units per minute, which is crucial in high-demand environments.

Accuracy is another vital aspect. Some high-speed systems can detect defects with an accuracy rate of over 99%. However, it's important to note that not all machines provide the same level of performance. Businesses must understand that what works for one operation might not suit another. A mismatched machine could lead to costly errors and waste.

Additionally, the integration process can present challenges. Training staff and adapting workflows to accommodate new technology often requires time and resources. It's crucial to carefully plan implementation strategies. A precision machine can yield great results, but without proper setup, it may only create confusion. In the end, the right choice hinges on understanding your unique operational needs and capabilities.

Why Choose a High Speed Inspection Machine for Your Business?

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| High Speed Processing | Able to inspect items at speeds exceeding 1000 units per minute. | Increases throughput, reducing bottlenecks in production lines. | Manufacturing, electronics, food packaging. |

| Precision Accuracy | Capable of detecting minuscule defects and inaccuracies. | Ensures high-quality standards, reducing returns and waste. | Quality control in various industries. |

| Adaptive Algorithms | Utilizes machine learning to adapt to new inspection criteria. | Flexible to change, reducing setup time for new product lines. | Any industry with frequent product updates. |

| User-Friendly Interface | Intuitive controls and dashboards for easy operation. | Reduces training time for operators and minimizes errors. | Applicable in all sectors requiring inspection machines. |

| Compact Design | Space-efficient without compromising performance. | Ideal for facilities with limited floor space. | Small to medium-sized production facilities. |