- 713.590.1312

- sale@pandbtools.com

Why Choose a Knife Gate Valve for Your Industrial Needs?

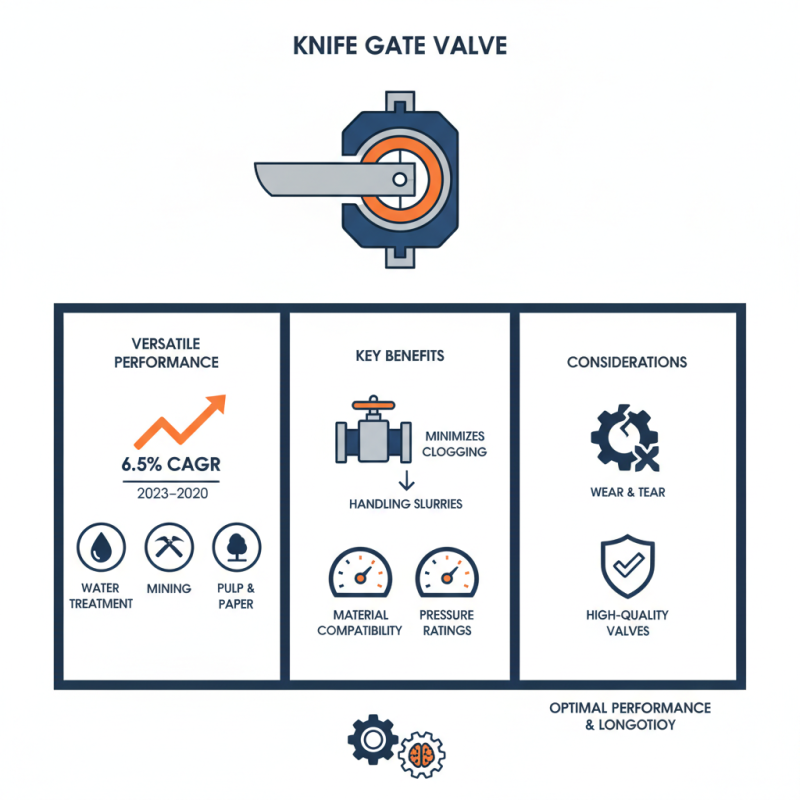

In the industrial sector, equipment choice significantly impacts operational efficiency. Knife Gate Valves have gained recognition for their versatile performance in diverse applications. According to a recent industry report, the global Knife Gate Valve market is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2030. This growth reflects increasing demand in sectors like water treatment, mining, and pulp and paper.

These valves are known for their simplicity and effectiveness in controlling flow. They are ideal for handling slurries, as their design minimizes clogging. However, not all Knife Gate Valves are created equal. Selection should consider material compatibility and pressure ratings. Misjudging these factors can lead to operational inefficiencies and increased maintenance costs.

While Knife Gate Valves provide benefits, they are not without challenges. Users must often deal with wear and tear, especially in abrasive environments. Investing in high-quality valves can mitigate these concerns. Thus, understanding their unique advantages and limitations is crucial for industries striving for optimal performance and longevity.

Understanding Knife Gate Valves and Their Industrial Applications

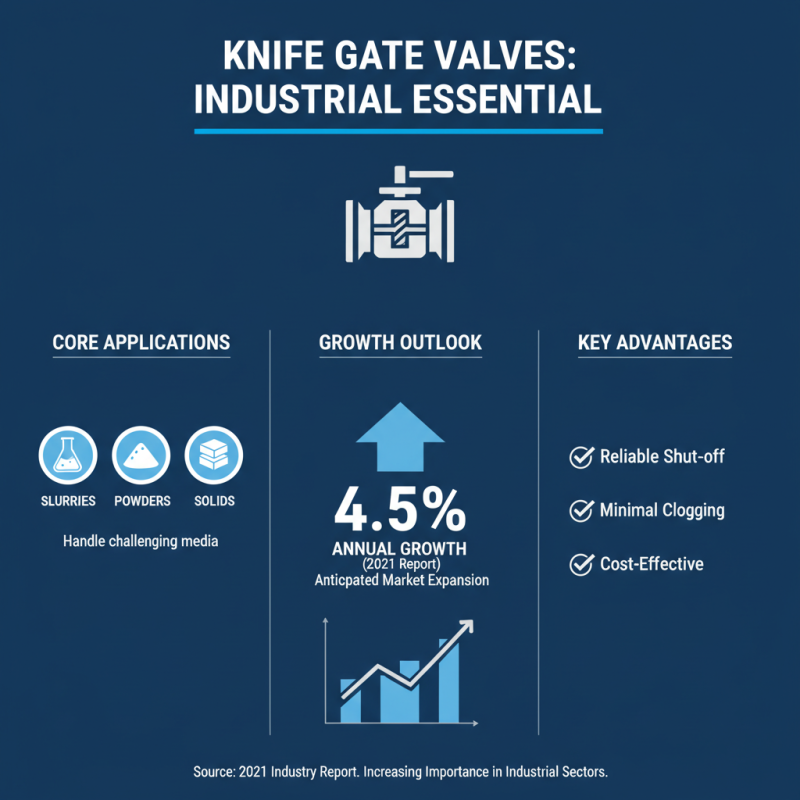

Knife gate valves are essential in many industrial applications. They excel in handling slurries, powders, and solids. According to a 2021 industry report, the demand for knife gate valves is anticipated to grow by 4.5% annually. This growth highlights their increasing importance.

These valves offer a unique design that allows for complete closure. The blade slices through the material, ensuring a tight seal. This feature is particularly valuable in waste management and mining sectors. A study found that knife gate valves reduce leakage rates by up to 30%. However, they can struggle with heavier solids.

In addition, maintenance can be a challenge. The wear on the blade may lead to performance issues over time. Regular inspections are critical to prevent failures. Operators often overlook this aspect. Proper training and knowledge are necessary to maximize efficiency. Understanding potential limitations can help in making informed choices.

The Key Advantages of Using Knife Gate Valves in Various Industries

Knife gate valves offer unique advantages in various industrial settings. Their design allows for effective control of flow in challenging media, such as slurries and solids. According to a report by Global Market Insights, the demand for knife gate valves is expected to grow by 5.5% annually through the next few years. This growth reflects the increasing needs of industries like wastewater treatment, mining, and pulp and paper.

One key benefit of knife gate valves is their ability to handle high pressures and temperatures. They excel in applications where conventional valves might fail. The American Water Works Association notes that these valves have a low risk of jamming, which can significantly reduce downtime. However, proper maintenance is vital. Neglecting regular inspections can lead to issues, including leaks or failures.

Moreover, knife gate valves are often more compact than traditional gate valves. Their slim profile suits tight spaces and helps in installation. However, some industries still overlook these benefits. They tend to stick with older technologies, missing out on efficiency gains. Embracing knife gate valves could enhance operational performance while also reducing costs associated with maintenance and energy consumption.

Factors to Consider When Choosing a Knife Gate Valve

When selecting a knife gate valve for industrial applications, there are several critical factors to consider. The pressure range of your system will significantly affect performance. Knife gate valves are ideal for systems that handle slurries, wastewater, or coarse materials. According to a report from the International Journal of Engineering Research and Applications, these valves perform best in environments where traditional ball or globe valves might fail.

Material choice is another crucial aspect. Knife gate valves are available in various materials, including stainless steel, cast iron, and plastic. Each material has specific properties that affect durability. For example, stainless steel offers corrosion resistance, while plastic may be more suitable for less aggressive environments. Assess your specific situation to choose wisely.

Tip: Always evaluate valve sizing. An incorrectly sized valve can lead to pressure drops and inefficient system performance.

Moreover, consider the valve's design features. Look for features like self-cleaning or bi-directional capabilities. These can reduce maintenance downtime and improve lifespan. However, be wary—too many features can complicate operations and lead to potential failures. Balancing features with simplicity is essential for optimal function.

Tip: Regular maintenance checks can significantly extend the life of your valve. Listen to operational feedback to spot issues before they escalate.

Maintenance and Care Tips for Knife Gate Valves

Knife gate valves are essential in many industries due to their ability to handle thick, abrasive slurries. However, proper maintenance is crucial to ensure their effectiveness and longevity. Regular inspections can prevent unexpected failures. A study found that valves with scheduled maintenance had a 30% longer lifespan compared to those neglected.

Tip: Always check for leaks during inspections. Small leaks can escalate into larger issues. Monitor the valve for signs of wear and tear. Pay attention to the seat and blade. These parts often show the most wear.

Additionally, lubrication plays a crucial role in the operation of knife gate valves. A well-lubricated stem ensures smooth operation. Industry reports indicate that regular lubrication can reduce friction by up to 40%. Neglecting lubrication causes undue stress and potential malfunctions.

Tip: Use appropriate lubricants available in the market. Avoid over-lubricating as it can attract dirt and debris. Keep a checklist for maintenance tasks to ensure every aspect is reviewed. Regular training for staff on maintenance procedures can also enhance valve performance significantly.

Comparing Knife Gate Valves to Other Valve Types in Industrial Use

When it comes to industrial applications, choosing the right valve is crucial. Knife gate valves offer unique benefits compared to other types. Their sharp-edged design effectively cuts through thick liquids and slurries, reducing wear and tear on components. This element is vital for operations involving viscous or abrasive materials.

In contrast, ball valves might struggle with similar media. They can wear out quickly when dealing with solids in suspension. Globe valves, while good for regulating flow, often lead to pressure drops, impacting efficiency. Knife gate valves provide a direct flow path. They allow for full opening and closing, which minimizes turbulence. This means less energy is wasted.

Tips: Always consider the media type. Thick slurries may need a knife gate valve, while clean liquids could suit other types better. Regular maintenance also affects performance. Check seals and operational efficiency periodically to avoid unexpected failures. Remember, not every installation is the same. Tailor your choice to the specific environment and requirements.

Why Choose a Knife Gate Valve for Your Industrial Needs? - Comparing Knife Gate Valves to Other Valve Types in Industrial Use

| Valve Type | Applications | Advantages | Disadvantages | Best Suitable Medium |

|---|---|---|---|---|

| Knife Gate Valve | Pulp and Paper, Wastewater Treatment | High resistance to abrasion, cost-effective for bulk handling | Limited flow control, may not be suitable for high-pressure applications | Slurries, liquids with solid particles |

| Gate Valve | Oil and Gas, Water Supply | Minimal pressure drop, good sealing | Not suitable for throttling, slower operation | Clean liquids and gases |

| Ball Valve | Chemical Processing, HVAC | Quick operation, good sealing | Can be expensive, less suitable for high solids | Various liquids and gases |

| Butterfly Valve | Water Treatment, Fire Protection | Compact design, lightweight | Less effective sealing, not ideal for high-pressure use | Water, air, and certain chemical applications |

Related Posts

-

Advantages of Using Knife Gate Valves in Various Industries

-

2025 Market Insights: Elevating Efficiency with the Best Knife Gate Valve Solutions

-

Understanding Industry Standards for the Best Knife Gate Valves

-

Unlock Global Excellence with China’s Premier Gate Valve Components

-

Exploring the Innovations Shaping the Future of Angle Valves

-

Innovations in Best Stainless Steel Ball Valves for 2025 Industry Trends and Future Solutions